Our state-of-the-art Thermal Spray Coating facility is equipped with cutting-edge technology designed to deliver superior coating solutions for industrial, petro-chemical, Oil & Gas applications.

Achieving exceptionally dense and durable coatings for maximum wear, corrosion, and heat resistance

Delivering high-efficiency coatings ideal for repair restoration, electrical conductivity, corrosion, wear, abrasion protection, and structural enhancement.

Cost-effective solutions for wear-resistant and anti-corrosion coatings.

Specialized for applying ultra-hard ceramic coatings to withstand extreme operating conditions.

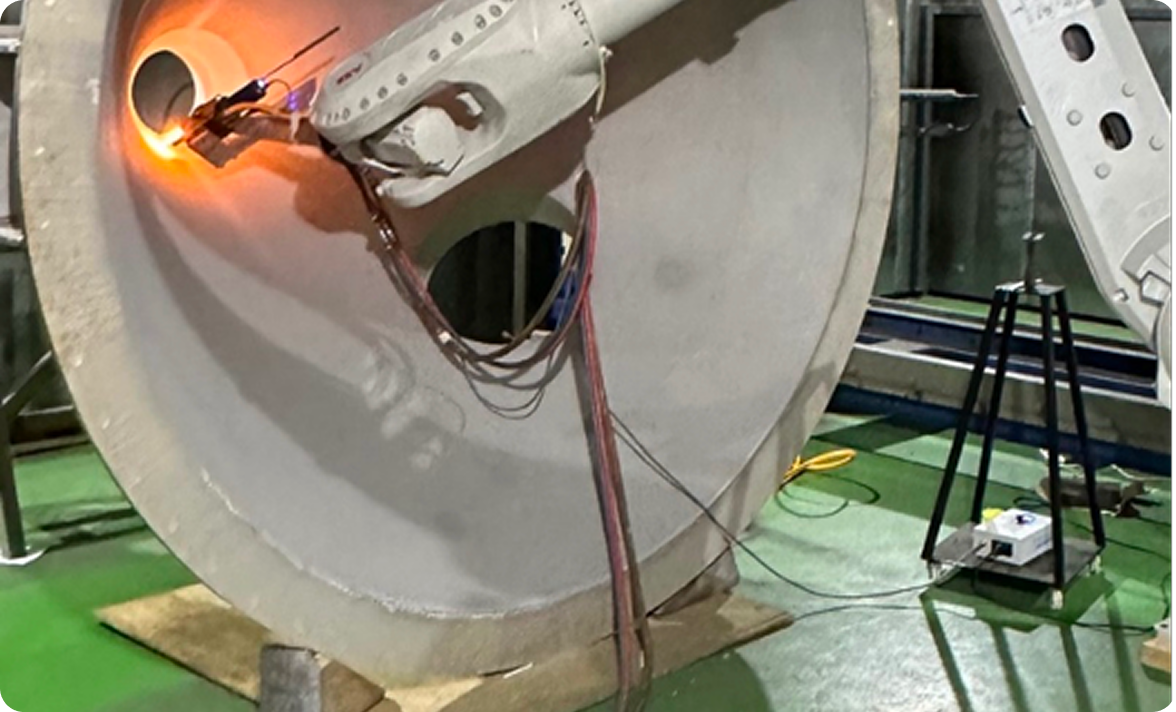

Measuring 10m in length, 7m in width, and 4.5m in height, our chamber can accommodate large components with ease

Engineered for heavy-duty operations, the gantry crane ensures seamless handling of large and complex parts.

Our thermal spray systems combine precision, efficiency, and versatility, making us the go-to solution for industries such as aerospace, automotive, oil and gas, and power generation. Whether you require protective, wear-resistant, or thermal barrier coatings, our advanced systems guarantee unmatched quality and performance.

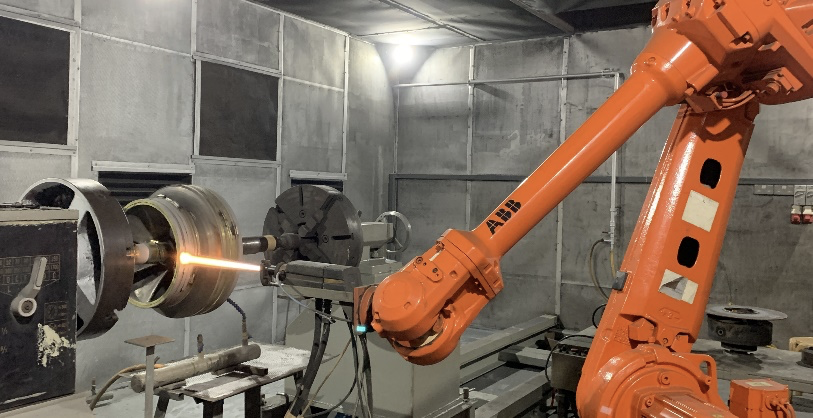

High velocity oxy fuel (HVOF) is a thermal spray process that uses a high-speed combustion flame to apply coatings with exceptional density and bond strength, a coating process most often used Tungsten carbide cobalt chromium (WC Co Cr) and chrome carbide, CrCNiCr are two of the most common powder materials used to replace Hard chrome, is the reason for their excellent corrosion, wear & abrasion resistance. Having a bond strength of greater than 10,000 psi and porosities of less than 1%.

Twin Wire Arc Spray (TWAS) is an advanced thermal spray process used to apply protective and functional coatings. It involves feeding two electrically charged wires of a specified material into a spray gun, where an electric arc melts the wire tips. The result is a high-performance coating with excellent adhesion, durability, and resistance to wear, corrosion, and high temperatures. This technique is widely employed in industries such as automotive, aerospace, oil and gas, and power generation to extend the lifespan and efficiency of critical components.

Flame Wire Spray is a thermal spray process that uses a fuel gas and oxygen flame to melt a consumable wire, which serves as the coating material. This process is versatile, cost-effective, and suitable for applying wear-resistant, anti-corrosion, and thermal barrier coatings. Commonly used in industries such as automotive, marine, and manufacturing, Flame Wire Spray enhances the performance and longevity of components by providing a robust protective layer.

Feel free to ask anything you want to know—no question is too big or small. We’re always here and ready to help!

I-Spray Pte Ltd is a highly-rated surface engineering service company serving the oil & gas, and other general industries located at Tuas, Singapore with a comprehensive workshop covering over 25,715 square feet.

17 Tuas View Place, Singapore (637863)

25 Tuas Avenue 13 #01-15, Singapore (638991)