Our Quality Control guarantees superior quality and precision through advanced inspection techniques, cutting-edge equipment, and adherence to international standards.

Detects surface defects in non-porous materials.

Identifies surface and subsurface discontinuities in ferromagnetic materials.

Evaluates internal defects using high-frequency sound waves.

All NDE inspections are performed by QC personnel certified with NDT Level II or higher, ensuring accuracy and compliance with industry standards.

Verifies coating adherence to substrates.

Identifies coating flaws such as pinholes and voids.

Ensures precise coating thickness measurements.

Detects surface contamination levels.

Assesses cleanliness for optimal coating adhesion.

Monitors ambient conditions during coating applications.

Measures surface roughness for coating preparation.

Coating inspections are conducted by certified NACE Level 2 Inspectors, ensuring compliance with stringent coating application standards.

Confirms correct alloy composition and ensures material traceability.

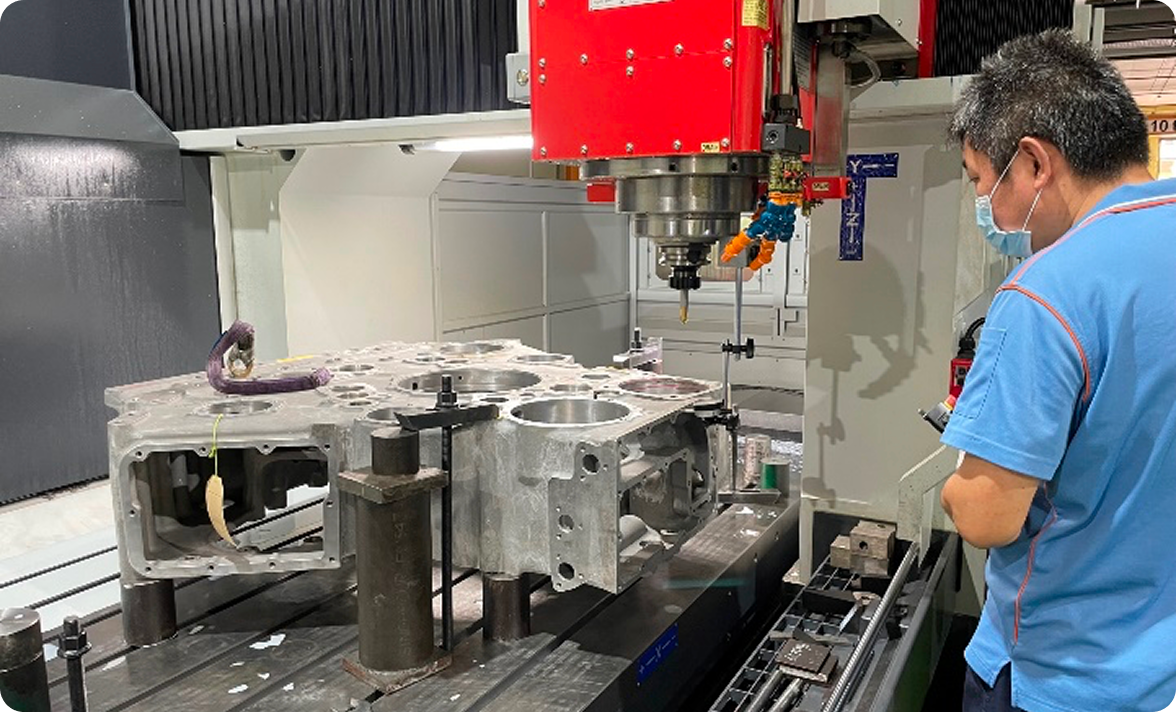

We offer comprehensive dimensional inspection using precision instruments to verify tolerances and ensure component accuracy.

Micrometers, calipers, height gauges, bore gauges and more.

Identifies surface and subsurface discontinuities in ferromagnetic materials.

Evaluates the stability and performance of rotating equipment.

Provides precise alignment of machinery components for improved operational efficiency.

Feel free to ask anything you want to know—no question is too big or small. We’re always here and ready to help!

I-Spray Pte Ltd is a highly-rated surface engineering service company serving the oil & gas, and other general industries located at Tuas, Singapore with a comprehensive workshop covering over 25,715 square feet.

17 Tuas View Place, Singapore (637863)

25 Tuas Avenue 13 #01-15, Singapore (638991)